Large format CNC machining is one of our core competencies

CMS Poseidon 5-Axis Machining Centers

The Poseidon is made specifically for large format machining projects: It never compromises rigidity or stability over the impressively large 83’ x 20’ work envelope.

With the Poseidon machines as the centerpiece of all three facilities we are fully optimized for precision machining of advanced composite materials. The Poseidon machines are certified to an overall volumetric tolerance of 0.1mm or .004”.

Machining Envelope

X = 26m /83.3’ Y = 6.2m /20.4’ Z = 3m /9.9’ A = +/-120° C = +/- 270°

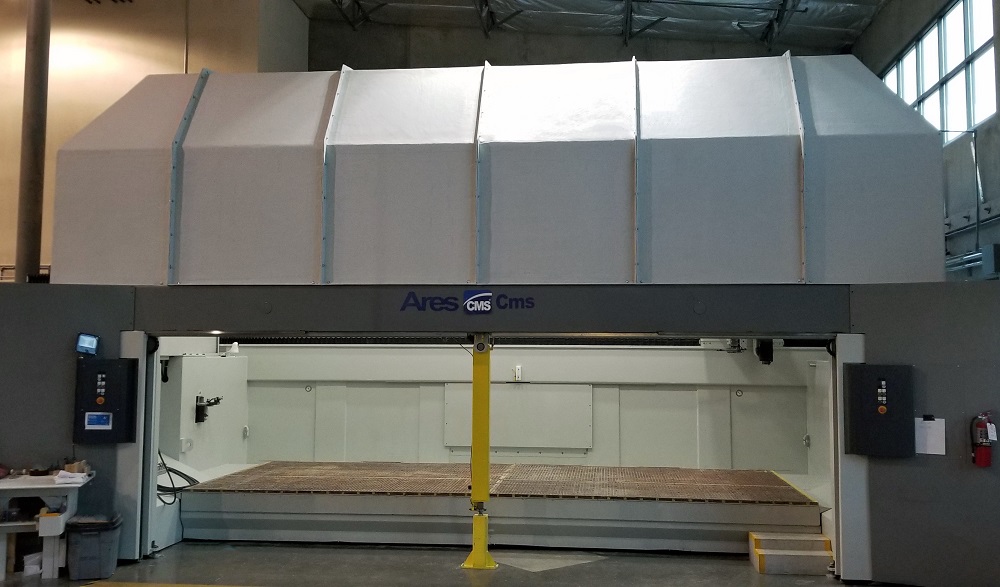

CMS Ares 5-Axis Machining Center

The Ares Machining Center in our Nevada facility extends the range of tooling materials we can process. The Ares combines high precision 5-axis capabilities with a rigid mono-bloc frame for accuracy and stability. It is also equipped with a vacuum table measuring 6 x 2.4 meters.

Machining Envelope

X = 6,000 mm/19.6’ Y = 2,600 mm/8.53’ Z = 1,200 mm/3.93’ B = +/- 120° C = +/- 270°

Precision Machining

Symmetrix employs a unique combination of sophisticated software, precision machining and expert craftsmen, resulting in highly accurate tooling. Our customers utilize molds produced with this high degree of accuracy to increases production flexibility and eliminate repeating errors, which results in significant cost savings.