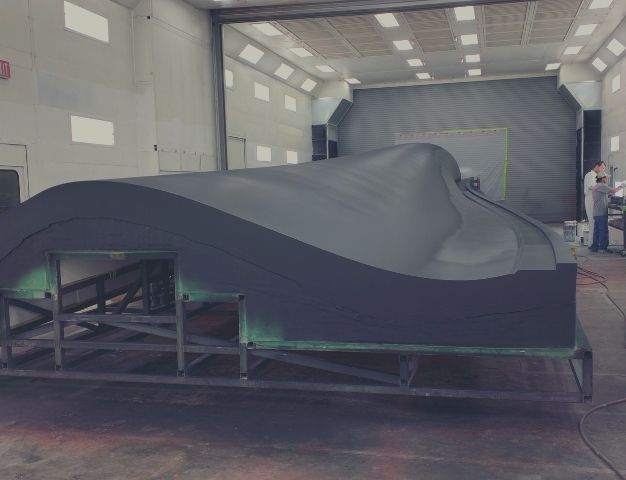

Where Innovative Design Takes Shape

Our experienced engineering and production teams plan, fabricate, finish, polish, and adjust every detail throughout the building process. A tool from Symmetrix sets you up for success, pull after pull. It is our people who create your unique composite form, mold, prototype, or plug and who ensure that it delivers maximum return on investment.