Project Info

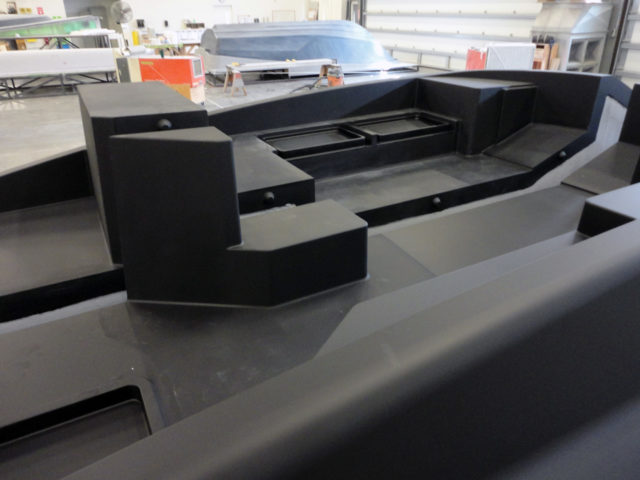

DTM hull tooling.

Client

Sabre / Back Cove Yachts.

Designer

Kevin Burns

Industry

Marine

Tooling Services

DTM Limited Production

Scope of Work

- CNC machined direct to mold hull surface measuring 185 m²

- Hydraulically actuated surface / See video: https://www.youtube.com/watch?v=p1v7tSn-wr8

- Split on centerline to accommodate the classic tumblehome hull shape

- Optimized to support closed molding vacuum infusion hull laminating process

- Engineered solutions to anticipate extreme exotherm during infusion: This surface had heat shielding material incorporated into the composite tooling laminate as well as thermocouple wiring for real-time measurement and management during the cure

- Single skin removable FRP transom mold

- Traditional deck pattern

Customer Testimonial

“Symmetrix gave us confidence to do something that had never been done before on such a large scale. From conceptualizing, researching and problem solving, to follow through with manufacturing and product – their project management started early on and continued through the whole project. We rely on agile partnerships so we can continue to focus on product development. Symmetrix is a true partner to us when it comes to difficult tooling operations and that is what is invaluable to us.”

Kevin Burns

VP of Design and Product Development, Sabre / Back Cove Yachts